| Carbon Fiber 3D Printers: Revolutionizing Strength and Durability in Additive Manufacturing |

|

|

|

อ้างอิง

อ่าน 66 ครั้ง / ตอบ 0 ครั้ง

|

pilla

|

Carbon Fiber 3D Printers: Revolutionizing Strength and Durability in Additive Manufacturing

Carbon fiber, known for its exceptional strength-to-weight ratio and durability, has traditionally been used in high-performance industries such as aerospace, automotive, and sports equipment. However, thanks to advancements in 3D printing technology, carbon fiber-infused filaments are now accessible to engineers, designers, and manufacturers of all sizes.

In this article, we’ll explore what carbon fiber 3D printers are, how they work, their key benefits, applications, and some challenges associated with using them.

What is a Carbon Fiber 3D Printer?

A carbon fiber 3D printer is a type of additive manufacturing system designed to print parts using carbon fiber filament or carbon fiber-reinforced composite materials. These materials are typically made by combining carbon fiber strands or filaments with a base thermoplastic polymer (such as PLA, ABS, or Nylon). The resulting composite material has the strength and rigidity of carbon fiber but retains the ease of processing of standard thermoplastics.

There are two primary types of carbon fiber 3D printing methods:

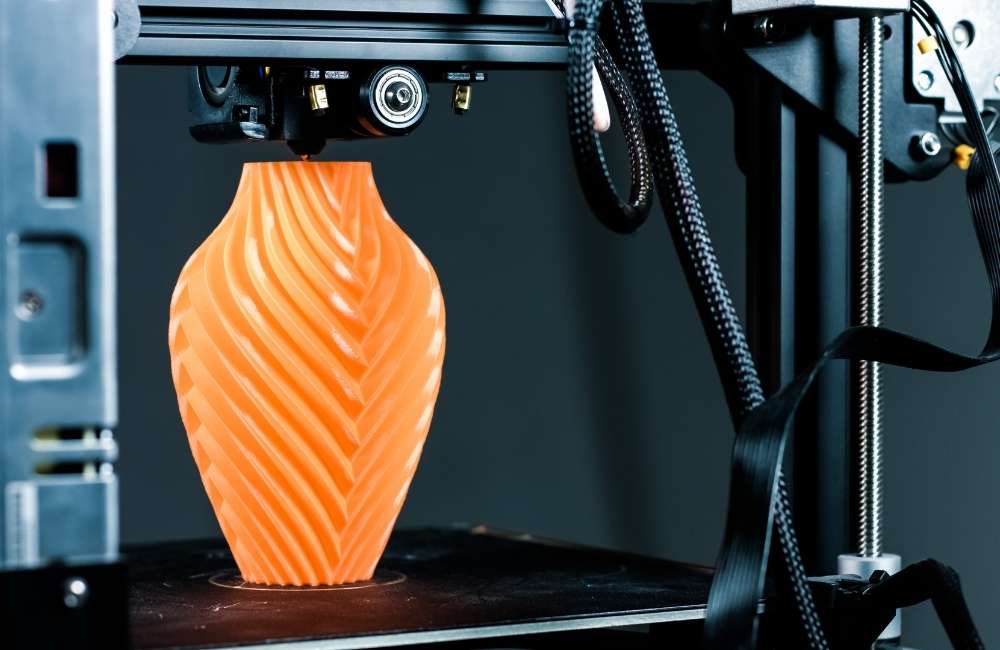

Filament-based 3D Printing (FDM/FFF): This is the most common method for printing carbon fiber-reinforced parts. In this process, carbon fiber strands are mixed with a base material like PLA, PETG, or Nylon to create a filament. The 3D printer then extrudes this filament layer by layer to build the object. The carbon fibers add strength and stiffness to the print, making it ideal for structural parts.

Continuous Carbon Fiber 3D Printing: This process is a more advanced technique that uses a continuous strand of carbon fiber embedded in a thermoplastic matrix. This allows for even higher strength and durability, as the carbon fiber is not just embedded in the material but runs continuously through the part, offering reinforcement in all directions.

|

| |

pilla [172.69.166.xxx] เมื่อ 26/11/2024 17:54

|